| Place of Origin: | China | Brand Name: | ALUDONG |

|---|

| Certification: | CE, ASTM, ISO, Green Leaf | Model Number: | 1100 |

|---|

| Detail Information |

| Specification: | 1220mm*2440mm; 1250mm*3050mm | Origin: | China Zhengzhou |

|---|

| Surface Finishing: | Coating | Panel Thickness: | 4mm |

|---|

| Aluminum Thickness: | 0.3mm | Function: | Fireproofing, Anti-static, Anti-Bacterial, Mould-proof |

|---|

| Usage: | External Wall, Curtain Wall, Interior, Advertising |

|---|

| High Light: | AA1100 Marble Aluminum Composite Panel,4mm Marble Aluminum Composite Panel,AA1100 Marble ACP |

|---|

Product Description

Marble Grantie Series Aluminum Composite Panel-Aludong

Product range:| Surface Coating | Polyester Coating |

| Aluminum Alloy | AA1100, AA3003 |

| Aluminum Skin | 0.10mm,0.12mm,0.15mm,0.18mm,0.21mm,0.25mm,0.30mm |

| Panel Thickness | 2mm,3mm,4mm,5mm |

| Core Material | Non-toxic low density polyethylene |

| Panel Width | 1000mm,1220mm,1250mm,1500, |

| Panel Length | 2440mm,3050mm,4000mm,5000mm |

| Back Coat | PE coating, Primer Coating ,Mill finish |

| Panel Width | ±2mm |

| Panel Length | ±3mm |

| Panel Thickness | ±0.2mm |

| Panel Diagonal | ≤ 5mm |

| Aluminum layer thickness | ±0.02mm |

| Description | Test standard | Polyester |

| Coating Thickness (μm) | Polyester paint >=16μm | 16μm to 18μm |

| Coating flexibility (T-bend) | Polyester paint ≤ 3T | ≤ 3T |

| Color different | ΔE<=2.0 (follow color sample) | ΔE<=2.0 |

| Pencil hardness | >=HB | >=2H |

| Chemical resistance | 2%HCI or 2%NaOH test in 24 hours -No change | No change |

| Coating adhesion | >=1grade for 10810mm2 gridding test | 1grade |

| Resist solvent | 100 times without change | No change |

| Boiling water resistance | 2 hours without change | No change |

| Peeling strength/stripping strength | Average >=5N/mm of 180oc peel off

for panel with 0.21mm alu.skin | 5N/mm |

| Impact test for paint | 20KG.cm impact-paint no split for panel | No split |

| Abrasion resistance (L/Mil) | NIL | NIL |

| Temperature resistance | -40ºC to +80ºC temperature without

change of color difference

and paint peel off, peeling

strength average dropprate<=10% | Change of glossy only, no paint |

| Peel off |

| Coefficient of linear Thermal Expansion | 100ºC temperature difference | 2.4mm/n |

| Detergent resistance (3%) | ASTM D2248 | No change |

| Humidity Resistance (3000hrs,100%RH,100°F) | ASTM D2247 | No change |

| Salt spray resistance (3000hrs,5% salt) | ASTM B117 | No change |

| Resistance to Staining | 600h radiate in 800W/M2 in humidity condition

,glossiness deviation less grade 2,color difference <=4.0 | No change |

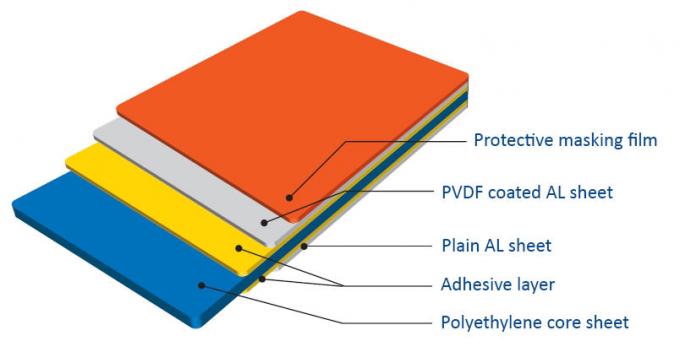

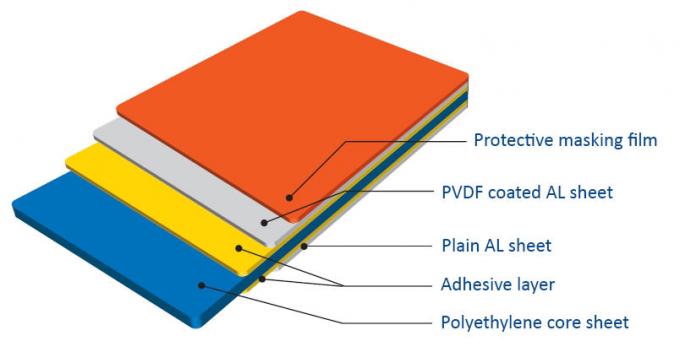

Aluminum composite panel structure:

Plastic cores: we have high quality 100% pure polyethylene cores to

ensure smooth surface and easy grooving.

Coils: we do coating by ourselves to guarantee the coating quality

and performance.

Plastic polyester film for protection: branded or clear film

Colors: matt,metallic,glossy,brushed,wood,granite,mirror,etc.

Aluminum composite panel usage:

*Interior cladding,ceiling,modular kitchen cabinet,countertop

*Exterior cladding,canopy,curtain wall,siding,roofing,building

elevation

*Signage,sopraporta,fascia,shop fronts,billboard,printing ETC.

How we stand out among our peers:

*Scale: We have 24 composite lines and 6 coating lines, making us

the largest manufacturer in China.

*Quality: Our strict quality control has passed CE, SGS, ROHS, ISO,

etc.

*Experience: Founded in 1999, we have rich production experience

and efforts to make Jixiang a well-known brand in China.

*Our scale economy and rich experience help ensure on-time delivery

and warranty.

*As a group colossal,our network synergy guarantees optimal cost

advantage.

*We have much experience with OEM/ODM.

*We have a wide range of specs and colors at your choice,including

tailor made projects.

*We are attentive,assiduous and responsible,WE VALUE EACH & EVERY

CUSTOMER for long term cooperation.

Our aluminum coils:

Composite Lines:

Packaging:

Loading: